|

|

Mechanical Compensation and Hydraulic Compensation Technology of Press brakeTime:2021-08-11

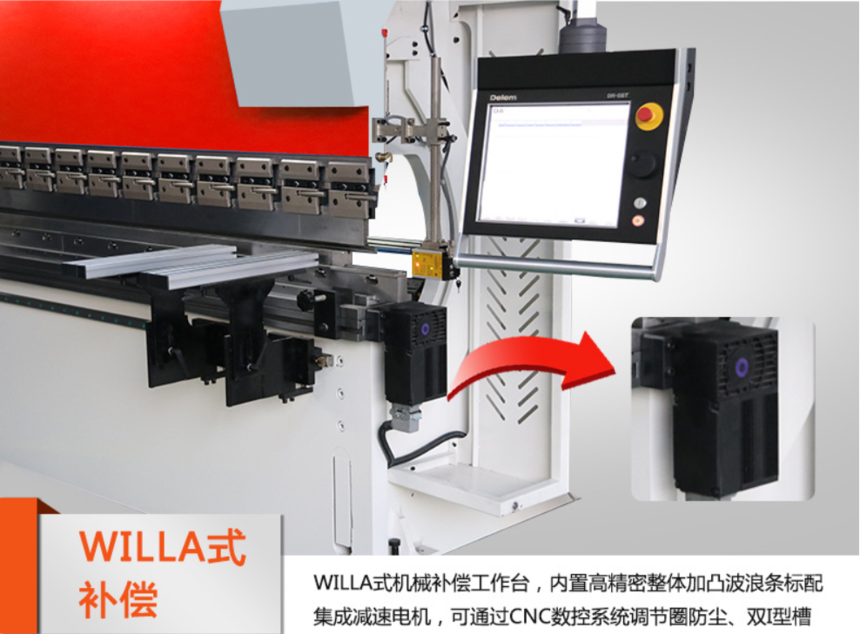

Mechanical equipment compensation technology: plus convex wedges are composed of a set of sloped plus convex oblique wedges, each plus convex wedge is based on the design plan of the deflection curve diagram of the guide rail slider and the working table. The numerical control machine tool calculates the required compensation amount according to the load force when the product workpiece is bent (this force will cause the deflection deformation of the guide rail slider and the bottom beam of the worktable), and the automatic control system adds the relative displacement of the convex wedge , And then reasonably compensate for the deflection deformation caused by the guide rail slider and the bottom beam of the worktable, can obtain the ideal bending product, the workpiece mechanical equipment deflection compensation is completed by the method of manipulating the "pre-protrusion", and a set of wedges work The length and short direction of the table produce a curve that matches the specific deflection, which promotes the same gap between the left and right grinding tools when bending, and ensures that the viewing angle of the bending product workpiece in the long and short directions is consistent. The compensation of mechanical equipment can be accurately compensated for the deflection of the total length of the worktable. The application of mechanical equipment deflection compensation has long-term reliability, reduces the frequency of maintenance of hydraulic machine compensation (such as oil leakage), and is maintenance-free during the service life of the CNC lathe. Because of the more compensation points for mechanical equipment deflection compensation, the bending machine can achieve linear compensation when bending the product workpiece during work, which can improve the actual bending effect of the product workpiece. The compensation of mechanical equipment is driven by a motor as a CNC machine tool axis, which completes intelligent operation and makes the compensation value more accurate. Compensation technology of hydraulic press: The automatic deflection compensation organization of the workbench hydraulic press is composed of a group of hydraulic cylinders installed in the lower workbench. The position and size of each compensation hydraulic cylinder are designed according to the deflection compensation curve diagram of the guide rail slider and the workbench finite element. The compensation of the hydraulic press is based on the relative displacement between the front and rear 3 bottom beams to complete the protrusion compensation for maintaining the neutral version. The basic principle is to complete the protrusion based on the elastic deformation of the thick steel plate itself, so the compensation amount can be in the workbench. The adjustment is completed within the scope of malleability.

|